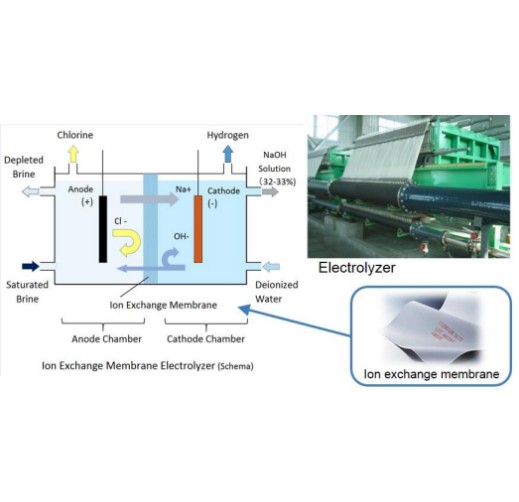

Ion-Exchange Membrane for the Production of Caustic Soda

Technology / Service Summary

This ion-exchange membrane method (membrane method) is characterized by not only the fact that no hazardous materials are used in it but also the fact that it enables significant energy conservation.

Purpose

Ion-Exchange Membrane for the Production of Caustic Soda

Feature

As the production of caustic soda from sodium chloride solution made from poorly refined raw materials which contains significant amount of impurities is on the increase in certain areas recently, the group developed “FLEMION™ F8080” in 2011 which can be used with voltage lower

than the voltage used for the previous membranes and, thus, consumes less electric power and which is strongly resistant to impurities in sodium chloride solution. Developed the “FLEMION F-9010™” achieving lower voltage and power consumption, and launched it commercially in 2019

Effect

The technology has realized approx. 40 % of energy reduction compared with the mercury method and the diaphragm method in the caustic soda production.

Controlled Substance

Applicable Regions / Countries

- Japan

- Southeast Asia

- Central/South Asia

- China/ East Asia

- Middle East

- Africa

- Oceania

- Europe

- Central/South America

- ASEAN countries

Indonesia,Cambodia,Singapore,Thailand,Philippines,Brunei Darussalam,Viet Nam,Malaysia,Myanmar,Lao PDR

Accomplishments

The technology used in the ion-exchange membrane method has been developed into one of the technologies which represent the technological excellence of Japan, with assistance and efforts made by many people involved in the development including those in the government. Its use in the commercial production began in 1979. The ion-exchange membrane method became the only caustic soda production method used in Japan in 1999. This technology, which has many advantages including high quality and energy conservation, is being exported to over 50 countries in the world.

Overseas, the ion exchange membrane method is mainstream, while the diaphragm method and mercury method are still used occasionally. Moreover, as the Minamata Convention on Mercury came into effect, caustic soda production using the mercury method will be banned by 2025. For this reason, it is expected that more and more manufacturers will switch to the ion exchange membrane method in the future.

The technology was successfully adopted JCM Model Project in 2016. (Introduction of High Efficiency Ion Exchange Membrane Electrolyzer in Caustic Soda Production Plant)

Related SDGs Goals

- 9. Industry, Innovation and Infrastructure

- 12. Responsible Consumption and Production

- 13. Climate Action