DDR Membrane - CO2 Separation for Natural Gas Treatment

Technology / Service Summary

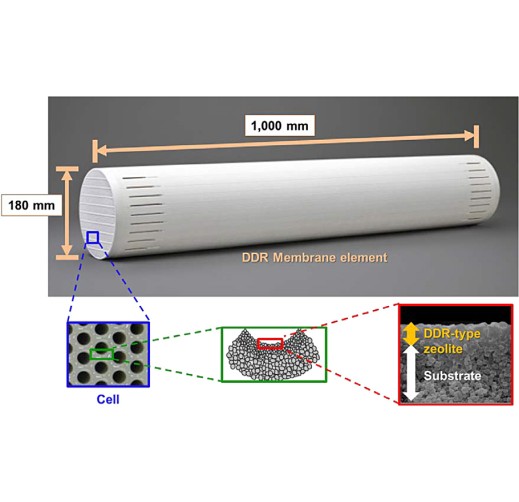

DDR membrane process is a high-efficiency CO2 separation technology using a DDR-type zeolite membrane. It is suitable for CO2 separation from associated gas deriving from CO2-EOR.

Purpose

Efficient CO2 recovery from natural gas including high CO2 concentration and promoting of CCS.

Feature

・Applicable to high pressure and high CO2 gas fields (high CO2 partial pressure durability)

・CH4 loss in DDR membrane process is much smaller than in conventional polymeric membrane process (Approximately 1/10 or less than conventional polymeric membranes)

・DDR membrane enables an economic, one-stage system

・DDR membrane can be adapted to changing, increasing levels of CO2 over time, by retrofitting

・The largest zeolite membrane element in the world, it can only be manufactured by NGK Insulators, Ltd.

Effect

CCS can be promoted by adopting this technology and efficiently separating and recovering CO2.

Controlled Substance

Applicable Regions / Countries

- Japan

- Southeast Asia

- Central/South Asia

- China/ East Asia

- Middle East

- Africa

- Oceania

- Europe

- Central/South America

- ASEAN countries

Indonesia,Cambodia,Singapore,Thailand,Philippines,Brunei Darussalam,Viet Nam,Malaysia,Myanmar,Lao PDR

Related SDGs Goals

- 7. Affordable and Clean Energy

- 9. Industry, Innovation and Infrastructure

- 13. Climate Action

- 17. Partnerships to achieve the Goal