HEMIX™ bioplastics utilizing agricultural, forestry, and fishery wastes

Technology / Service Summary

Hemicellulose Ltd. has an integrated manufacturing process from extraction to resin pellet production (from entry to exit of waste agricultural, forestry, and fishery products).

(1) Identification of extraction conditions and extraction of hemicellulose components from waste products, (2) Purification of hemicellulose-containing aqueous solution with activated carbon, etc. to improve purity, (3) Concentration and drying of hemicellulose components to powder, (4) Chemical synthesis to improve functions such as strength, heat resistance and transparency, (5) Compounding with other bioplastic resin

Purpose

Rather than using plant resources that are newly cultivated or harvested (e.g., using edible corn and sugarcane for bioplastics), we manufacture "bioplastic resin derived from agricultural, forestry, and marine products" using "unused resources" that already exist but are being incinerated or discarded because no use can be found for them.

This is a manufacturing activity to “make full and effective use of existing plants and trees,” and contributes to the control of CO2 emissions and reduction of CO2 emissions in comparison with conventional manufacturing methods.

In order to replace petroleum-based plastic products (e.g., food and beverage containers, cosmetic containers, and interior parts for automobiles, aircraft, space rockets, and rail vehicles) with plant-based products, we develop new technologies such as injection molding, blow molding, sheet molding, film molding, and melt spinning to contribute to a “decarbonized society” and develop bioplastics with properties adaptable to various molding methods and promote carbon neutrality in various industrial applications.

Feature

There are many solid molded products such as containers using bioplastics in the world, but we are developing not only solid molded products (e.g., tumblers, cosmetic containers, etc.) but also 1 mm thin sheets/films and 100% bio-fibers/yarns using HEMIX™, a bioplastic material utilizing hemicellulose. We are also developing thin sheets/films of about 1 mm and 100% bio-fibers/threads. No other company is working on a product that combines three fields of bioplastic materials (injection molding, sheet/film, and fiber/yarn).

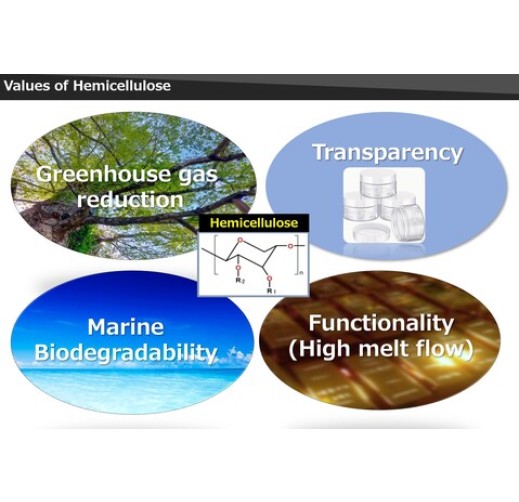

Hemicellulose is easy to mold and process due to its high fluidity, which is unprecedented among bioplastic materials. It is also highly biodegradable in the ocean and rivers, with more than 90% decomposed in 180 days, making it a strong differentiating factor among various biopolymer materials.

Our products serve not only as commercial materials, but also as “environmental educational materials” that convey the significance and potential of decarbonization. For example, 10 high schools in Fukushima Prefecture collaborated to conduct marine biodegradability experiments using our plant-derived and biodegradable resin containers, and an educational program for elementary and junior high school students hosted by Kawasaki City used our products to give a lecture on plant-based plastics and CO2 reduction. The program was a great success.

Effect

【CO2 reduction effect】

(1) Conversion from petroleum-based plastics to bioplastics = Reduction of CO2 emissions in the manufacturing process of petroleum-based plastics (CO2 absorption through photosynthesis)

Hemicellulose is a generic term for polysaccharides that are 20-30% contained in trees and plants in general. It accounts for 500 million tons of the world's wood production (1.8 billion tons per year), but most of it has been disposed of or burned, except for a small portion used for food and cosmetic additives. In converting from petroleum-derived plastics, which are used in large quantities for packaging containers and materials, to bioplastics, the utilization of hemicellulose, which has a particularly high unutilized ratio among the various components, has great potential for future expansion because of its large CO2 emission reduction and because it does not compete with other applications.

(2) Disposal Utilization of components derived from agricultural, forestry, and fishery products = reduction of greenhouse gas emissions during disposal and combustion

Hemicellulose is also contained in “waste biomass” (food residues, pomace, etc.) and “unutilized biomass” (inedible parts such as shells and bones, leftover forest, etc.). By collaborating with agricultural, forestry, and fishery businesses prior to disposal, we will recover waste products, extract hemicellulose, and turn it into products, thereby contributing to the reduction of CO2 emissions during disposal and combustion.

Controlled Substance

Applicable Regions / Countries

- Japan

- Southeast Asia

- Central/South Asia

- China/ East Asia

- Middle East

- Africa

- Oceania

- North America

- Europe

- Central/South America

- ASEAN countries

Indonesia,Singapore,Thailand,Viet Nam,Malaysia

Related SDGs Goals

- 1. No Poverty

- 8. Decent Work and Economic Growth

- 9. Industry, Innovation and Infrastructure

- 11. Sustainable Cities and Communities

- 12. Responsible Consumption and Production

- 13. Climate Action

- 14. Life Below Water

- 15. Life on Land

- 16. Peace, Justice and Strong Institutions

- 17. Partnerships to achieve the Goal