Kurita Dropwise Condensation Technology

Kurita Water Industries Ltd.

Carbon Neutral Group, Innovation Division

Technology / Service Summary

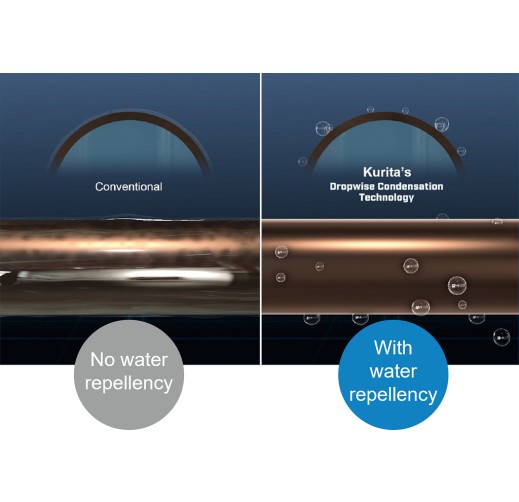

A dropwise condensation technology enables water repellency of heat exchangers while eliminating the water film to improve the heat transfer efficiency, boost productivity, and save energy.

Purpose

Kurita Dropwise Condensation Technology is one of our unique technologies that contributes to reducing CO2 emissions through energy conservation.

In recent years, energy conservation in the manufacturing industry is one of the unavoidable efforts in response to soaring fuel prices due to changes in the world situation and toward the realization of carbon neutrality, but many energy conservation initiatives have already been implemented. However, it is often difficult to promote further energy conservation because it requires finding new ideas for initiatives and large capital investments such as installing equipment to implement measures.

This technology is based on an unprecedented concept of improving the efficiency of heat transfer from the steam side to the heat exchanger, improving the productivity of production equipment and reducing the amount of steam used, which accounts for a large proportion of energy in factories. This contributes to energy conservation (reducing CO2 emissions), etc.

Feature

This technology has been introduced in many facilities because it has a large improvement rate in heat transfer coefficient and is easy to apply.

The specific procedure for application is simply to create a chemical injection point in the steam line just before the target heat exchanger.

In other words, this technology can be introduced while production equipment is in operation.

In addition, in addition to renting the equipment necessary for installation from our own equipment, we also package on-site support and data analysis, which eliminates large initial costs and equipment ownership, and reduces the labor required for the customer. providing.

Additionally, in Japan, it has received the 2019 Energy Conservation Award (product/business model category) and the 2022 Kanto Invention Award and Invention Encouragement Award.

Effect

In steam-heated heat exchangers, the water film that forms in the heat transfer area due to steam condensation is the main factor that inhibits heat transfer.

This technology changes the form of steam condensed water from a filmwise to dropwise by adsorbing a special chemical added to the steam onto the metal surface of the heat transfer part of the heat exchanger and making it water repellent. This improves heat transfer.

By suppressing the formation of a water film, which is a factor that inhibits heat transfer, the overall heat transfer coefficient (U value), which is an index of how easily heat transfers, can be improved by up to 30%.

Controlled Substance

Reference

Applicable Regions / Countries

- Japan

- Southeast Asia

- Central/South Asia

- China/ East Asia

- Europe

- Central/South America

- ASEAN countries

Indonesia,Singapore,Thailand,Philippines,Viet Nam,Malaysia,Myanmar

Accomplishments

This technology is applicable to all heat exchangers that use steam, and as it can be applied to many types of heat exchangers, it has been introduced in a wide variety of industries and processes.

Specific examples include dryer processes in paper mills, corrugators in cardboard factories, condensers in power generation turbines, and reaction vessels in chemical factories.

For example, in the dryer process for drying wet paper in a paper mill, the application of this technology has improved the heat transfer coefficient, contributing to a 5-10% improvement in steam consumption and a reduction in CO2 emissions.

In addition, production volume has increased by improving drying defects.

It is being applied not only in Japan but also overseas, and has been introduced in over 300 cases both domestically and overseas.

Related SDGs Goals

- 7. Affordable and Clean Energy