Reduce NOx concentration without sacrificing clinker production and cost

TAIHEIYO ENGINEERING CORPORATION

Oversea Sales Dept.

Technology / Service Summary

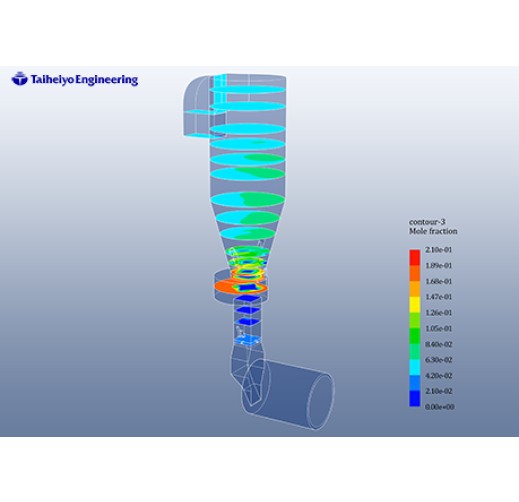

Pulverized coal is fed from Burner at kiln inlet and it is blown upward into kiln exhaust flow.

The blown pulverized coal burns with combustion of volatile matter and NOx is reduced.

Purpose

Recently, the regulation of NOx emission from cement plants has been getting stricter in the world for environmental protection. To keep the regulation, We have developed its original two-stage combustion technology.

Feature

1.No impact for clinker production process

・Some additional burners (De-NOx burners) are installed at kiln inlet for two-stage combustion. Fuel for the De-NOx burners is distributed from fuel for calciner (no need to increase fuel amount for calciner before and after installing the De-NOx burners).

・A part of raw meal at upper cyclone with low temperature is bypassed to near the De-NOx burners to prevent coating problem.

2.Low investment cost

・Main equipment is;

- Calciner burner

- De-NOx burners

- Fuel distribution box

- Raw meal diverter

Effect

NOx emission reduction: Target 30-50%

*Depending on the present NOx emission level and fuel characteristics

Controlled Substance

Reference

Applicable Regions / Countries

- Southeast Asia

- China/ East Asia

- ASEAN countries

Indonesia,Cambodia,Singapore,Thailand,Philippines,Brunei Darussalam,Viet Nam,Malaysia,Myanmar,Lao PDR

Accomplishments

・Japan

・China

・Taiwan

・Korea

・Vietnam

Reference URL

Locations for inspection

China

Related SDGs Goals

- 9. Industry, Innovation and Infrastructure

- 13. Climate Action