SS1N: Free Float® Steam Trap for Main Lines

TLV CO., LTD.

TLV International, Inc.

Technology / Service Summary

Steam mains typically carry a small amount of condensate. Steam traps for main lines operate for long hours and are often installed outdoors. SS1N is an ideal steam trap for such applications.

Purpose

Steam traps for main lines should have the lowest possible functional steam loss to minimize operating cost over the long term and provide long, reliable service, contributing to reduced steam consumption and CO2 emissions.

In addition, continuous condensate discharge prevents condensate retention, which can cause water hammer and corrosion, and can also prevent sudden plant shutdowns.

Feature

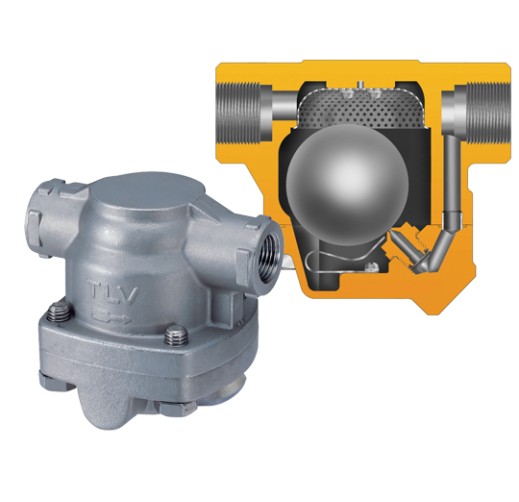

As with Free Float® steam traps in general, a constant water seal is present to prevent steam loss under normal operation. For applications involving the almost no-load conditions of superheated steam, the 3-point seated Free Float® traps are ideal.

The automatic air venting mechanism fully opens the valve opening to rapidly discharge any air and condensate at start-up. This can eliminate the need to open a bypass valve each time the equipment is started up and then close the valve after the line is purged, which saves on the cost of labor.

Because the Free Float® itself - a precision-ground hollow sphere - is the valve, the entire surface of the float functions as the sealing component. This guarantees superior reliability and long service life.

Effect

Environmental preservation and improvement effects include a two-fold reduction of CO2 emissions: through the reduction of not only functional steam loss, but also parts and materials through the reduced necessity of maintenance.

Controlled Substance

Applicable Regions / Countries

- Japan

- Southeast Asia

- Central/South Asia

- China/ East Asia

- Middle East

- Africa

- Oceania

- Europe

- Central/South America

- ASEAN countries

Indonesia,Cambodia,Singapore,Thailand,Philippines,Brunei Darussalam,Viet Nam,Malaysia,Myanmar,Lao PDR

Related SDGs Goals

- 13. Climate Action